Keypoints

- Modulating burner: Optimal temperature control throughout the day and maximum seasonal energy efficiency.

- Peripheral air circulation: Rear air intake and front hot air supply for optimal peripheral air circulation and best temperature uniformity.

- Easy to install, economical to maintain: Fastening eyebolts and large inspection doors reduce operating costs to a minimum.

- Dry environment and maximum productivity: Producing clean and dry warm air, substantially improving the environment, and increasing productivity.

- Versatile and very safe: Designed and manufactured with materials and components suitable for operation in extreme temperatures and aggressive environments, the machine has combustion air intake and flue gas exhaust to the outside.

Warm Air Heaters

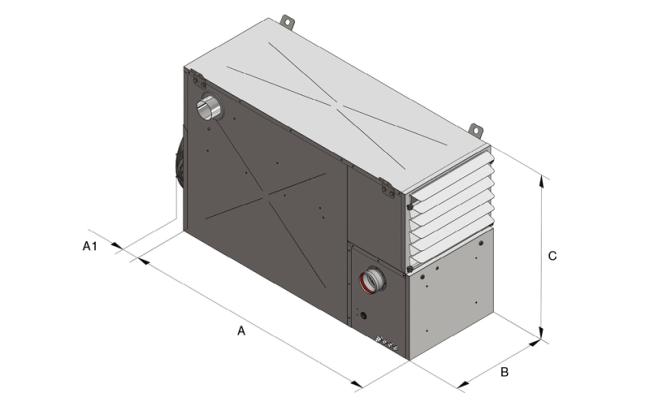

EKOCIKKI PLUS Suspended gas-fired room sealed heaters for direct

air diffusion with modulating premix gas burnerto 7.500

EKOCIKKI PLUS are suspended Gas-fired heater using a modulating premix gas burner produced with a scope to guarantee an optimal diffusion of the warm air in the poultry farm and it has the advantage of introducing only clean air into the treated environment, not contaminated by any type of pollutant such as carbon dioxide, carbon monoxide, nitrogen oxides and humidity.

Product informations

The heating of poultry farms with the air heater mod. EKOCIKKI PLUS equipped with an air - flue gas heat exchanger, brings the following and undisputed advantages:

- Release of CLEAN AIR only into the environment, free of any type of contaminant such as carbon dioxide (CO2), carbon monoxide (CO) and nitrogen oxides (NOx); in some cases that sense of "heaviness" in the air caused by the odorants that are added to the fuel for safety reasons is also avoided.

- Injection of "dry" air into the environment as the steam produced by combustion is all discharged outside, with the advantage of a less humid environment, less prone to receiving bacterial loads and with less need for air renewal to reduce the 'relative humidity.

- It greatly improves the welfare of the animals; the quality and quantity of the meat produced and helps to reduce the rates of disease and mortality.

- Lower operating cost, as the thermal power only serves to compensate for the "inevitable" needs, that is, the heat loss of the envelope and the heating of the renewal air necessary to make the animals "breathe"; it is therefore no longer necessary to add thermal power to compensate for an additional air change that is necessary when mixing air heaters are used; which release the carbon dioxide present in the combustion products into the environment.

- The modulating thermal power operation allows to satisfy the instant thermal need without frequent ON-OFF and / or internal temperature swings, and to increase the overall efficiency of the air heater.

- Compared to mixing air heaters, the air flow rate is significantly higher while the air temperature and outlet speeds are lower. This means moving - recirculating the internal volume of the shed many times every hour, which results in a better and effective air distribution, with reduced vertical stratification and in the absence of annoying drafts.

- All the "delicate" components of the appliance (electrical panel, burner, gas solenoid valve, thermostats, etc.) are contained in a dedicated technical compartment that is not in communication with the treated air; this means a guarantee of duration and very few cleaning interventions.

- The design ergonomics and simplicity of the device make the device reliable, long-lasting and there is no need for special skills and abilities for its operation.

- The intake of indoor air only, without outdoor air, effectively eliminates those transient moments in which the mixing air heater (during the pre-wash phase) introduces unpleasantly cold air into the environment. Furthermore, if desired, it is possible to make the fan unit work in continuous mode and switch on - switch off the burner only upon request for heating; this improves the distribution and uniformity of air temperature and reduces the "condensing" effect of the high relative humidity normally present inside the farm.

- A "sealed" configuration with respect to the environment to be heated allows the clean air needed for combustion to be taken from outside. This feature therefore allows the installation of the device in harsh conditions even in dusty environments.

|

Description |

U.M. |

Model |

|---|---|---|

|

EKOCIKKI PLUS |

||

|

MAX nominal heating capacity input (burned) |

kW |

110 |

|

kcal/h |

94.600 |

|

|

MIN nominal heating capacity input (burned) |

kW |

41 |

|

kcal/h |

35.260 |

|

|

Nominal air flow |

Nm3/h |

7.500 |

NOTES:

• Operation in condensing mode is not forseen.

• The warm air heaters EKOCIKKI PLUS are prearranged to work with G20 natural gas. The conversion kit to propane gas G31 can be ordered separately.

• The remote control panel is an essential accessory for correct operation of the heaters.

WARM AIR HEATER consisting of:

- Heat exchanger completely made of stainless steel.

- External casing made of pre-painted or powder-coated galvanized steel, with thermal insulation of the surfaces most exposed to the heat exchanger radiation, with burner inspection door.

- Eyebolts for heater suspension.

- Premix burner with low CO and NOx emissions, with wide regulation range, including semi-radiant flame tubular, modulating mixer and gas-air solenoid valve, DC brushless fan, ignition and ionisation electrodes for flame control.

- Axial fan suitable to work with temperatures down to -25°C, with electrical motor three-phase 400V 50Hz 3N.

- Multifunctional electronic board for control and protection of the warm air heater: ambient temperature control, burner start up, flame supervision and safety functions.

- Safety temperature probe for overheating shutdown.

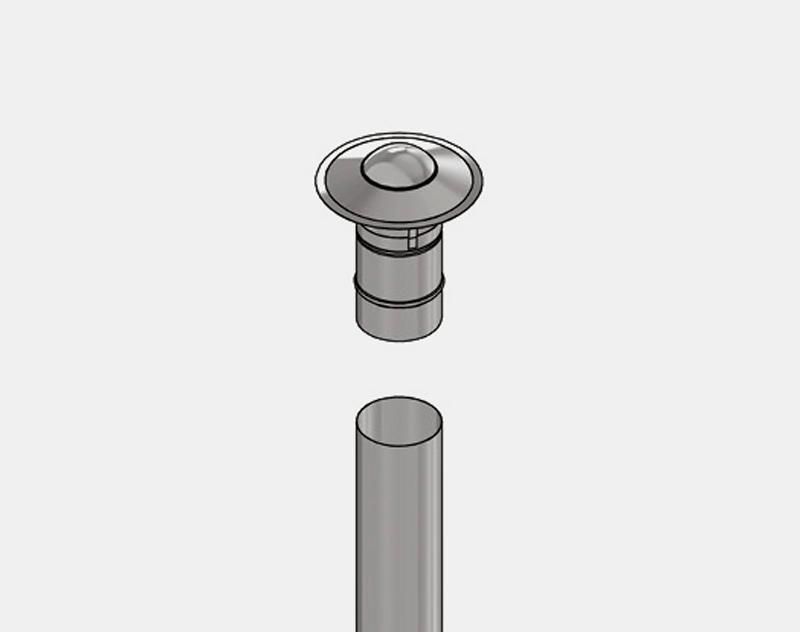

- Combustion air intake and flue exhaust connectors.

DELIVERY: Ex works our factory.

PACKAGE: Warm air heaters are wrapped in cardboard and pallet-loaded.

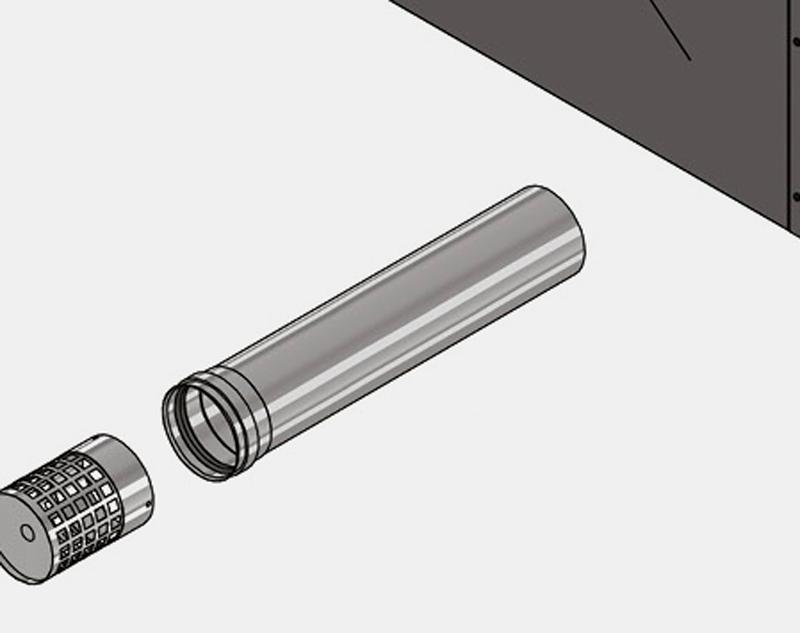

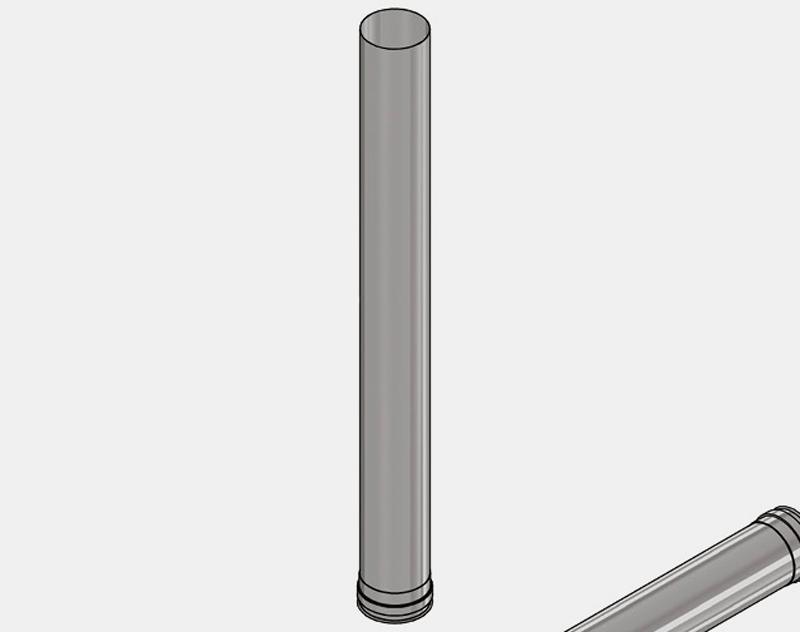

-

Stainless steel exhaust pipe L=0,5 m

-

Stainless steel exhaust pipe L=1,0 m

-

90° stainless steel elbow

-

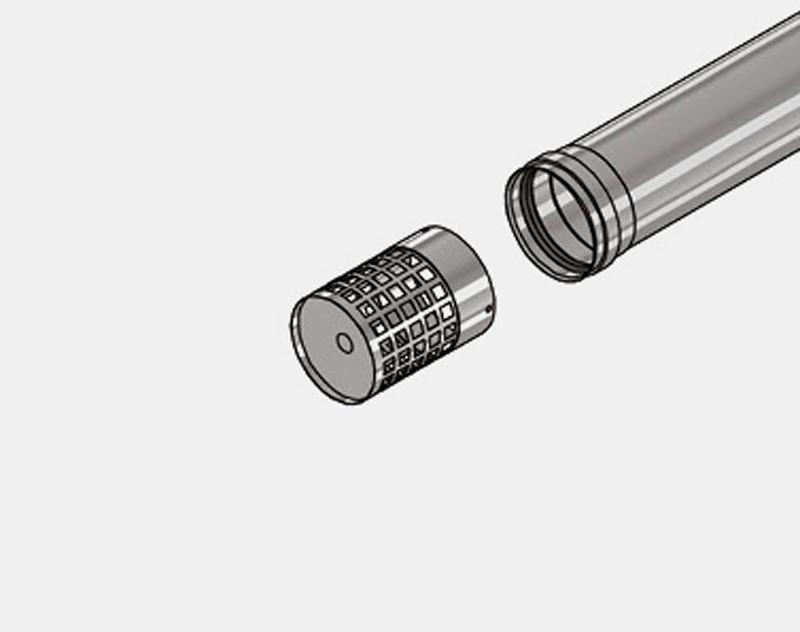

Wall terminal

-

Stainless steel rain cap