Keypoints

MANCANO KEYPOINTS

Warm Air Heaters

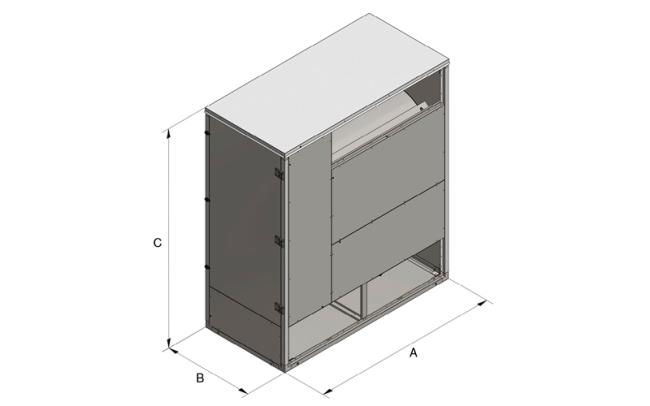

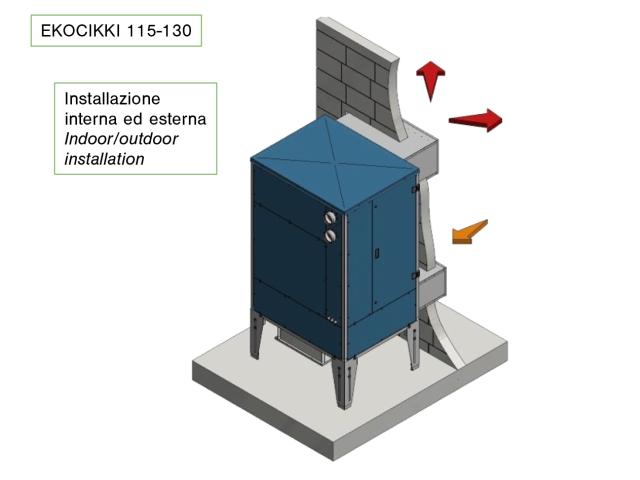

EKOCIKKI 115-130 High efficiency indirect-fired cabinet

warm air heaters for poultryOil

to 8.000

EKOCIKKI responds to the growing breeders need to have air heating systems with clean air. The increased power (130 kW) compared to SUPERCIKKI and less need of ventilation to assure air renewal thanks to the indirect heat exchange technology allow to install less EKOCIKKI heaters with obvious advantages from the point of view of efficiency and energy consumption.

Totally sealed combustion chamber reduces excess of humidity in the environment, eliminates completely the supply of CO2, CO and NOx resulting from the combustion residues, reduces the need of ventilation and ensures a healthy growth environment for animals. The combustion chamber and smoke tubes of EKOCIKKI are entirely made of stainless steel AISI 430.

Product informations

EKOCIKKI heater provides direct air distribution (does not require air ducts). It can be configured for external or internal installation and allows to mix the necessary amount of internal return air with fresh outside air. EKOCIKKI can be installed outdoors without any additional protection saving precious inside spaces for breeding.

The combustion is made with a blown burner: extremely reliable technology that ensures a stable operation of the

heater even in the most demanding conditions. The adoption of this technology allows the use of gas and oil burners

(no need to modify the product) and to have prompt competent assistance.

|

Description |

U.M. |

Model |

|

|---|---|---|---|

|

EKOCIKKI 115 |

EKOCIKKI 130 |

||

|

Nominal heating capacity input (burned) |

kW |

115 |

130 |

|

kcal/h |

98.900 |

111.800 |

|

|

USEFUL heating capacity output |

kW |

106,0 |

120,0 |

|

kcal/h |

91.160 |

103.200 |

|

|

Nominal air flow |

Nm3/h |

8.000 |

8.000 |

WARM AIR HEATER consisting of:

- Heat exchanger with three smokes rounds, completely made of stainless steel, complete with burner mounting plate, an inspection door, chimney connection and safety condensate drain connection.

- External casing in pre-painted galvanized steel with thermal insulation provided by means of aluminized steel internal panels and glass wool.

- Fan section with one axial fan complete with electric motor and safety grid.

- Electrical board for control and protection, designed for electrical supply 400V 50Hz 3N, complete with FAN-LIMIT triple-thermostat.

- Switch for selection of operating mode Heating-Stop-Summer ventilation.

- For oil burner version: single stage forced draught oil burner complete with electric device, nozzle and flexible pipes.

- For gas burner version: single stage forced draught gas burner complete with electric device and gas train.

NOTES:

• The gas trains for burners are designed to work with normal supply pressure (20 mbar for natural gas and 30 mbar for LPG).

• The burners are supplied equipped with safety/control devices and usual supply accessories foreseen by the supplier.

DELIVERY: Ex works our factory.

PACKAGE: Warm air heaters are wrapped in cardboard and pallet-loaded. Accessories are protected in cardboard or plastic film.

1. Alarms inspection panel.

2. Blown burner.

3. Electric board.

4. Safety thermostat.

5. Heat exchanger.

6. Axial fan.

7. Heat exchanger inspection door.

8. Combustion air intake.

9. Flue gas connection.

-

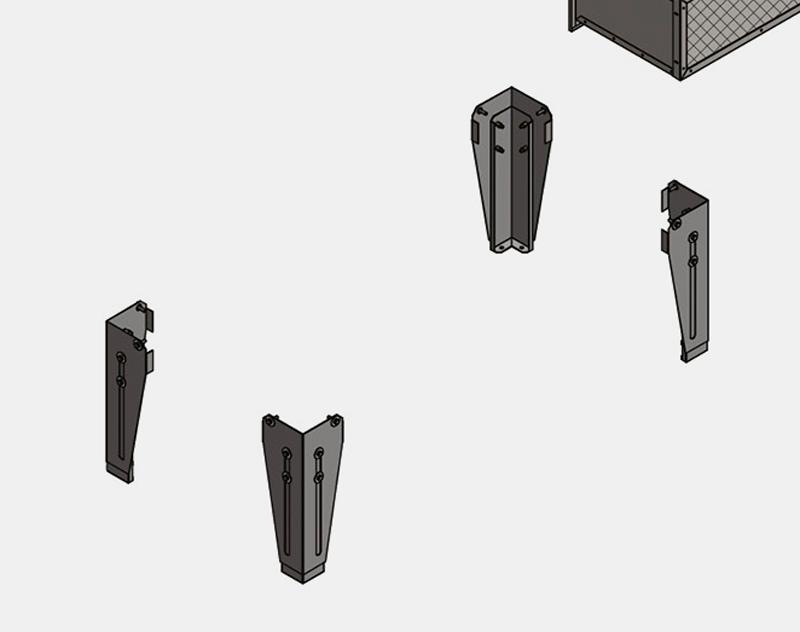

Set of adjustable supports

-

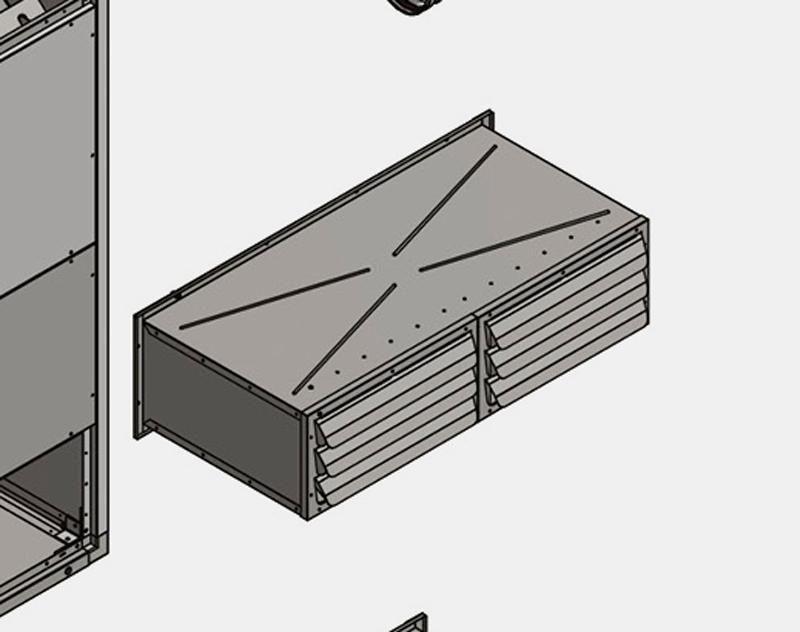

Supply air duct

-

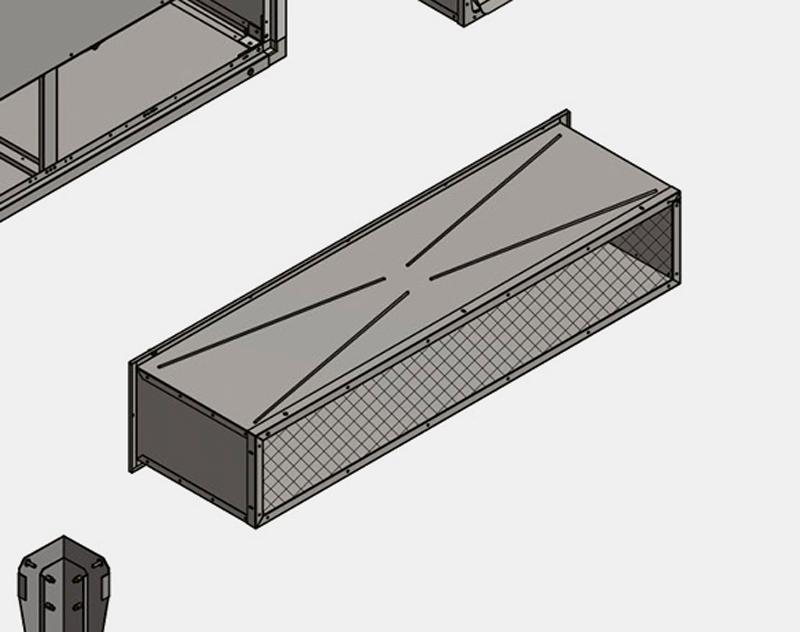

Intake air duct with protection grid

-

Electronic room thermostat

-

Sealed room thermostat

-

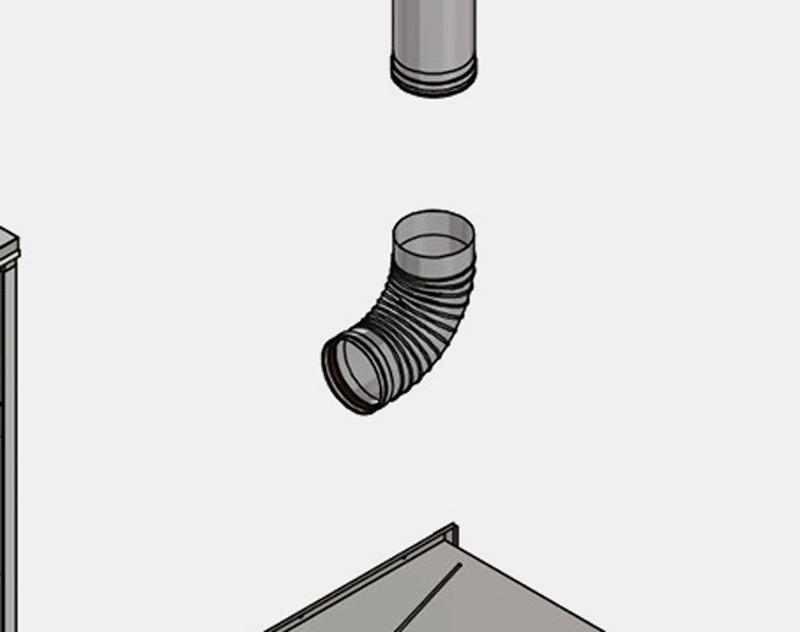

90° inox elbow Ø150

-

Inox pipe L=1000

-

Inox rain cap Ø150