Warm Air Heaters

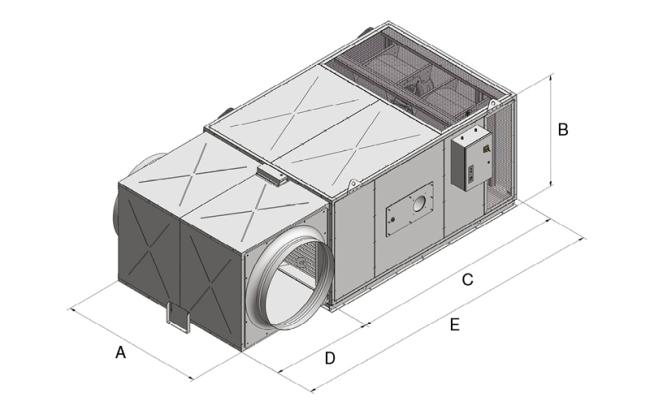

TCO-DF High efficiency horizontal warm air heaters

with side air flow outletOil

to 36.000

High-efficiency heater TCO series "down-flow" horizontal version, gas or oil-fired, which heats air mainly for greenhouse structures, with a duct system where diffusion through a ground air distribution system is required.

Product informations

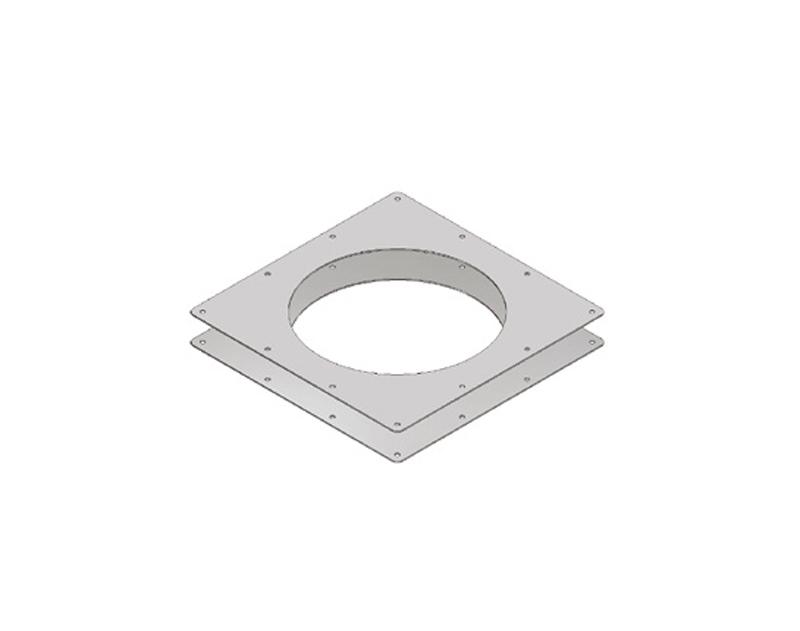

The equipment consist mainly of an isolated External casing receiving the air flow produced by the ventilator group. The External casing contains a high-efficiency INOX stainless steel heat exchanger which transfers the thermal power by means of direct exchange between combustion products and the air flow to be treated Such air is heated when passing onto the exchanger’s hot surface and it is then distributed to the premises. The warm air heater, if connected to main sleeves with secondary branch sleeves, allows the heating only the plant’s sensitive parts such as roots and leaves, thereby creating a kind of “drip heating” through an air-to-ground distributing device, granting a global energy saving. The centrifugal fan’s characteristics make the equipment suitable to be installed where air is to be distributed through pipings or - more generally - where high static pressure is required. The warm air heater is complete with electrical device for heater functions control and a particular flange (both outlet- and inletwise) allows equipment connection to the pipings.

On request all the models are available for functioning with double stage or modulating burners for the total control of the greenhouse's temperature. This allows to reach the maximum global plant efficiency.

CONSTRUCTION CHARACTERISTICS

- External casing - consists of a steel sheet supporting structure, with detachable closing panels internally lined with radiation-proof heat insulation and finely epoxy-painted.

- Fan group - includes one or more centrifugal double intake fans, statically and dynamically balanced, driven through a variable gear transmission by an electric motor complete with belt tightner.

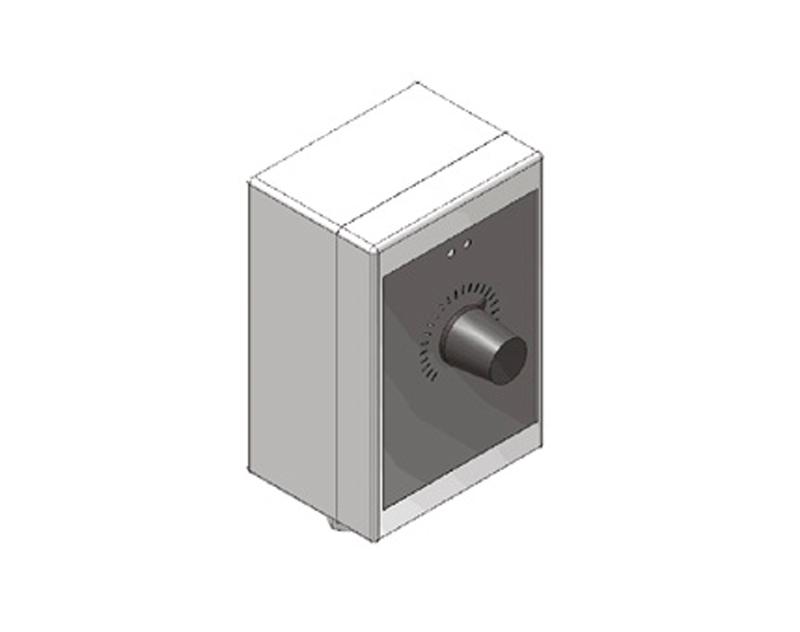

- Electric equipment - for automatic or manual fan control and for the emergency stopping of the burner in case of air overheating. Inclusive of electric switchboard and FAN-LIMIT double thermostat.

Heat exchanger: heart of the equipment

- Combustion chamber - made of AISI 430 18% chromium INOX stainless steel, flame-inversion model with low thermal load, cylindrical or ellipsoidal, perfectly cooled in all of its points.

- Exchange elements - made of AISI 430 18% chromium INOX stainless steel plate exhaust flues, flat tubular sections, with swirl impressions for maximum thermal efficiency.

- Exhaust manifold - front and rear, made of AISI 430 18% chromium INOX stainless steel, with wide inspection doors for rational and easy cleaning.

|

Description |

U.M. |

Model |

|||

|---|---|---|---|---|---|

|

TCO-DF 190 |

TCO-DF 255 |

TCO-DF 390 |

TCO-DF 590 |

||

|

Nominal heating capacity input (burned) |

kW |

190,0 |

258,8 |

391,0 |

590,0 |

|

kcal/h |

163.400 |

222.568 |

336.260 |

507.400 |

|

|

USEFUL heating capacity output |

kW |

168,2 |

230,3 |

347,6 |

523,2 |

|

kcal/h |

144.652 |

198.058 |

298.936 |

449.952 |

|

|

Nominal air flow |

Nm3/h |

12.500 |

16.000 |

23.500 |

36.000 |

|

Useful static pressure |

Pa |

150 |

150 |

150 |

150 |

NOTE: Available on request the version heat exchanger with smoke pipes in AISI 304 stainless steel and condensate discharge.

WARM AIR HEATER consisting of:

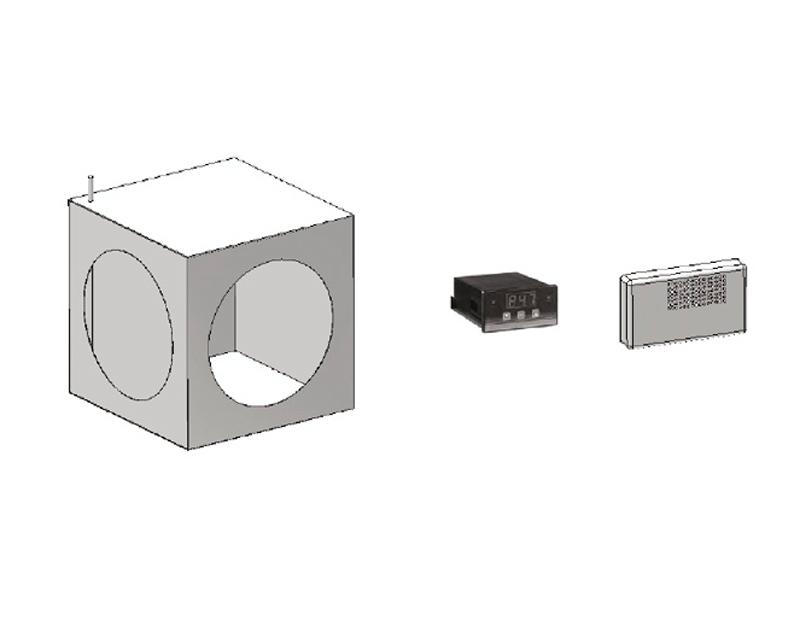

- Heat exchanger three smokes rounds, with combustion chamber and smoke pipes made of AISI 430 stainless steel, inspection doors, chimney connection and burner mounting plate.

- External casing in pre-painted galvanized steel with thermal insulation.

- Fan section with one or two centrifugal fans, complete with electric motor(s) and variable belt transmission.

- Electrical board for control and protection of the warm air heater designed for 400V 50Hz 3N three phase electrical motor, complete with FAN-LIMIT double-thermostat (n° 1 with manual reset and n° 1 with automatic reset) for TCO-DF 190/255/390 models or with FAN-LIMIT double-thermostat (n° 1 with manual reset and n° 1 with automatic reset) and a safety FLOW SWITCH for insufficient air flow control for TCO-DF 590 model.

- Bottom air outlet plenum with two circular duct panels for the connection of the polyethylene sleeve.

- Support frame.

- For oil burner version: single stage forced draught oil burner complete with electric device, nozzle and flexible pipes.

- For gas burner version: single stage forced draught gas burner complete with electric device and gas train.

NOTES:

• The gas trains for burners are designed to work with normal supply pressure (20 mbar for natural gas and 30 mbar for

LPG).

• The burners are supplied equipped with safety/control devices and usual supply accessories foreseen by the supplier.

• The burners are supplied disassembled and in separate packages. They have to be mounted, connected and set on site by the customer.

DELIVERY: Ex works our factory.

PACKAGE: Warm air heaters are wrapped in plastic film and pallet-loaded. Accessories are protected in cardboard or plastic film.

• Fan group - includes one or more centrifugal double intake fans, statically and dynamically balanced, driven through a variable gear transmission by an electric motor complete with belt tightner.

• Electric equipment - for automatic or manual fan control and for the emergency stop of the burner in case of air overheating. Inclusive of electric switchboard and FAN-LIMIT double thermostat. High efficiency heat exchanger.

• Combustion chamber - made of inox Aisi 430 18% chromium stainless steel, flame inversion model with low thermal load, cylindrical or ellipsoidal, perfectly cooled in all of its points.

• Exchange elements - made of inox Aisi 430 18% chromium stainless steel plate exhaust flues, flat tubular sections, with special prints for maximum thermal efficiency.

• Exhaust manifold - front and rear, made of inox Aisi 430 18% chromium stainless steel, with wide inspection doors for rational and easy cleaning.