Alfonso Vescovi

tecnoclima®

Air heating for sacred architecture

Alfonso Vescovi’s personal experience in heating hundreds of churches in Italy and the world, including: Cathedral of Cracovia, Cathedral of Pécs, St. Stephen’s Cathedral of Vienna, Cathedral of Beauvais, Montecassino Abbey, Basilica of Sant’antonio in Padua, Duomo Cathedral in Trento, San Marco church in Rovereto, has made it possible to create and patent the Sistema Alfonso Vescovi, condensing heating system, controlled air temperature, thermal power modulation, variable air flow rate

Opportunity to apply for governmental incentives thanks to the very high technical performance of the appliances. If requested, the possibility to install a «Turnkey» system starting from inspection up to the ignition and testing of the appliance.

Keypoints del Sistema Alfonso Vescovi

|

Environment particularity |

Necessary conditions |

|

|---|---|---|

|

Occasional use of the indoor environment, only during functions |

|

The high-ef ciency ENERGY series condensing air heaters are the ideal solution for occasional heating of large rooms, because they allow a quick start-up and maintenance of the temperature during the programmed time slots, and then a complete shut-down when the heating is no longer needed. The touchscreen control panel allows hourly and weekly programming and the selection of manual operating mode. The thermal ef ciency of the generators up to more than 100% allows an important saving in fuel consumption. |

|

Places of worship with elevated height |

|

The ENERGY series heaters are equipped with a temperature probe on the warm air outlet, to control and keep the supply temperature constant on the maximum set limit, through burner modulation. The thermal power and the air ow rate are progressively reduced as the environment heats up, drastically reducing the warm air strati cation phenomenon. |

|

Silent environment during function |

|

In addition to the variable air ow rate, which allows quiet operation during the temperature maintenance phase, the fan section of the generator and possibly the burner are optimized, by applying soundproo ng insulation to reduce noise emissions at the source. The generator's equipment for high-pressure operation allows the possible usage of silencers on the air ducts. |

|

Presence of architectural and cultural assets to be safeguarded |

|

The possibility of delivering the generator in several disassembled elements is foreseen to allow installation in con ned and dif cult-toaccess places. |

|

Condizioni necessarie |

|

|---|---|

|

Expensive heating systems that use water, which are very invasive and in exible, require a long time to get the environment up and running with inadequate comfort and excessively high operating costs. |

"SMART" management with two operating modes, one of fast preheating at maximum air ow and heat output, for quick room setting, the other of maintenance, with reduced air ow and thermal power, for comfortable and very silent operation during celebrations and the consequent minimum energy consumption. |

|

The excessive temperature, which can even exceed 60 ° ÷ 70 ° C and the uncontrolled temperature (on/off burners), does not allow the correct management of the parameters in the room. |

Controlled delivery temperature, with a maximum limit of 35/40°C, to drastically reduce the phenomenon of air strati cation and to optimize air diffusion and temperature homogenization. |

|

The high temperature tends to create upward convective motions with the dragging of dust (especially in the absence of speci c lters) and the accumulation of heat upwards and in the aisles. |

Fan section and burner expressly designed and optimized to reduce noise emissions at source and eliminate the phenomena of dust carbonization. |

|

The old type of heating systems with thermal gradient excessive and relative air temperature too high or radiant heating systems that excessively overheat the air that touches the surfaces, are solutions that usually tend to carbonize the dust, causing the possible blackening of plasters and paintings. |

Intake air ltration, with speci c lters to eliminate the emission of dust into the environment. |

|

In order to have 15°/18°C at the level of the people in the Church, there is a risk to have an extremely high temperature in the upper part of the nave and this can seriously damage the paintings and the wooden artifacts, both for phenomena of too rapid thermal expansion and for the reduction of relative humidity. |

Very high energy ef ciency to reduce consumption to a minimum and respect the environment. |

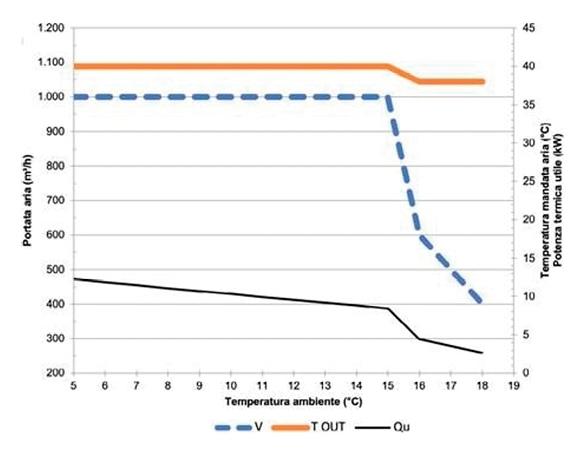

- Starting from the "very cold" church (+5°C), the appliance operates at the maximum air ow rate (eg. V=1.000 m³/h); the thermal power generated by the burner will be such as to keep the air delivery temperature constant (T OUT=+40°C).

- As the room temperature increases, always at air ow and max. air ow temperature, the thermal power generated by the burner is automatically reduced.

- This operation is carried out until the room temperature does not reach the value of +15°C which corresponds to the set-point.

- Starting from the ambient temperature value of +15°C, the air ow progressively reduces to the average value (e.g. V=600 m³ / h), the thermal power generated by the burner becomes such as to keep the reduced delivery temperature constant (T OUT = +38°C).

- If the room temperature again drops below 15°C, then the operating mode returns to maximum again until the temperature corresponds to the desired temperature.

- Once the set-point value had been reached, in order to avoid possible and unpleasant ON-OFF operation of the appliance during the religious function, an additional differential of +2°C has been inserted.

During this condition, the air ow progressively reduces further (e.g. V=400 m³/h) and the thermal power generated by the burner is such as to keep the reduced ow temperature (+38°C).

If the ambient temperature exceeds +17°C (15°C + 2°C), the device turns off.

If the ambient temperature drops instead below the set-point value (15°C), the appliance will re-ignites at medium speed (e.g. v=600 m³/h and 38°C).

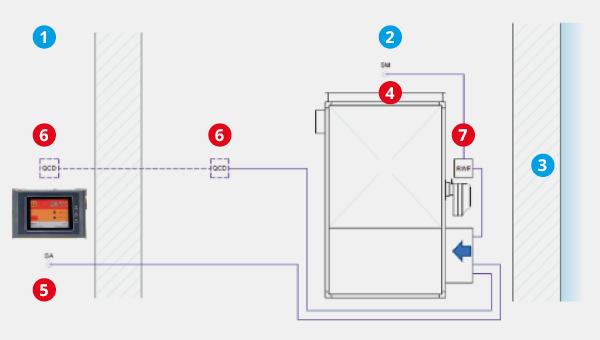

Operating scheme

- Church interior

- Central heating plant

- Exterior

- SM: flow temperature probe

- SA: room temperature probe

- QCD: remote control panel

- RWF: burner regulator