Keypoints

- High energy efficiency

- Flexible application

- Versatile and simple operation

- Double energy source for heating CF-XTRIM/P

- Gas-fired heating with thermal efficiency up to 106%

- Air renewal

- Thermal recovery with M-RCFX

- Refrigerant R410A

- Cooling capacity - thermodynamic cycle from 28 to 204 kW

- Heating capacity - gas heating from 28 to 204 kW

- Heating capacity - heat pump from 21 to 172 kW

- Air flow from 3.500 to 26.000 m3/h

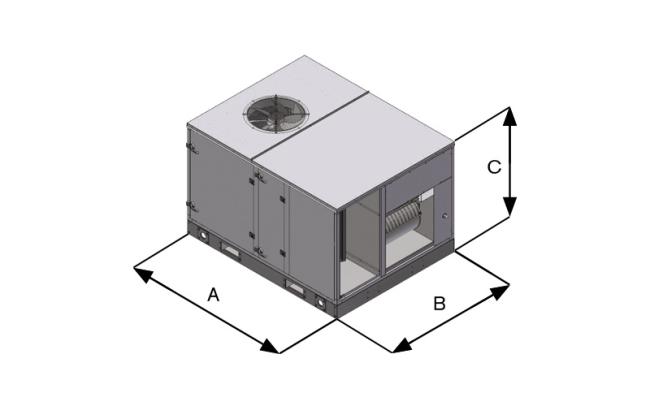

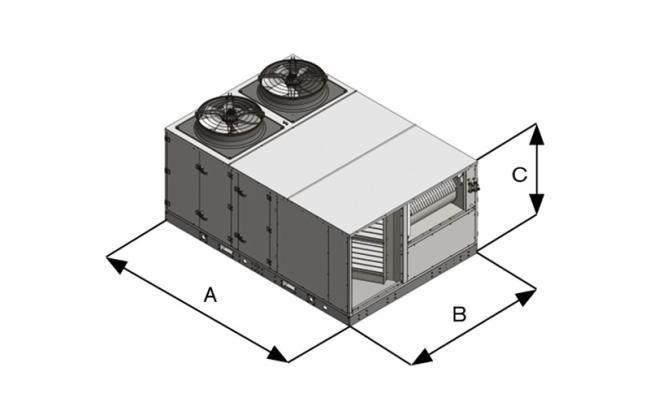

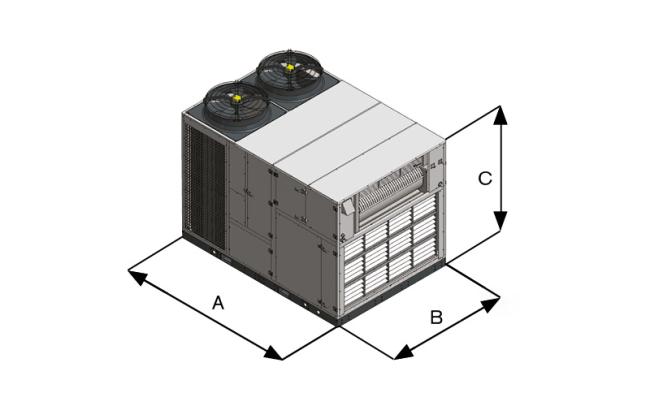

Roof top units

CF-XTRIM/HP Packaged autonomous air treatment units roof-top

(heat pump without gas module)Cold

capacity

to 164

to 26.000

ROOF-TOP CF-Xtrim are packaged autonomous air handling units designed for cooling & heating, cooling, filtration and air renewal with heat recovery module.

Product informations

ROOF-TOP CF-XTRIM are packaged autono-mous air handling units designed for gas heating and/or cooling & heating, cooling, filtration and air renewal with heat recovery module.

Tecnoclima CF-XTRIM units are designed to simplify as well as minimize installation operations and to achieve high energy efficiency in the air conditioning of the treated environments supported by intelligent and advanced autonomous management of thermal or cooling energy in relation to the actual needs of the treated environments: heating or cooling only when necessary.

Tecnoclima CF-XTRIM units are available in multiple versions and configurations to meet diversified application needs. Suitable for medium/large volume environments, such as stores, show rooms, gyms, supermarkets, malls, cinemas, theaters etc.

The units can be configured for high-efficiency energy recovery in applications where it is necessary to provide air renewal ensuring an excellent level of comfort and at the same time meeting the reference Laws and Regulations.

|

Description |

U.M. |

CF-XTRIM (with gas module) (3) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

CF-XTRIM/F (only cooling, without gas module) |

||||||||||

|

100 |

200 |

300 |

400 |

500 |

550 |

600 |

700 |

|||

|

Nominal air flow |

Nm3/h |

3.500 |

6.000 |

7.500 |

9.700 |

12.800 |

17.000 |

21.000 |

26.000 |

|

|

Useful static pressure |

Pa |

250/450 |

||||||||

|

GAS HEATING - HEATING CAPACITY MODULATION |

||||||||||

|

Heating capacity input (burned) |

max |

kW |

29,1 |

58,2 |

67,6 |

99,6 |

118(*) |

118(*) |

165,8 |

206,8 |

|

min |

kW |

9,4 |

9,4 |

9,4 |

18,4 |

20 |

20 |

18,4 |

33,3 |

|

|

THERMODYNAMIC COOLING |

||||||||||

|

Total cooling capacity output (1) |

kW |

22,8 |

35,0 |

48,0 |

65,9 |

92,5 |

110,6 |

139,8 |

171,6 |

|

|

Description |

U.M. |

CF-XTRIM/P (heat pump and gas module) (3) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

CF-XTRIM/HP (heat pump without gas module) |

||||||||||

|

100 |

200 |

300 |

400 |

500 |

550 |

600 |

700 |

|||

|

Nominal air flow |

Nm3/h |

3.500 |

6.000 |

7.500 |

9.700 |

12.800 |

17.000 |

21.000 |

26.000 |

|

|

Useful static pressure |

Pa |

250/450 |

||||||||

|

GAS HEATING - HEATING CAPACITY MODULATION |

||||||||||

|

Heating capacity input (burned) |

max |

kW |

29,1 |

58,2 |

67,6 |

99,6 |

118(*) |

118(*) |

165,8 |

206,8 |

|

min |

kW |

9,4 |

9,4 |

9,4 |

18,4 |

20 |

20 |

18,4 |

33,3 |

|

|

THERMODYNAMIC HEATING - HEAT PUMP |

||||||||||

|

Heating capacity (2) |

kW |

21,0 |

31,7 |

47,1 |

64,9 |

89,1 |

110,8 |

134,6 |

172,3 |

|

|

PDC COOLING PERFORMANCE |

||||||||||

|

Total cooling capacity output (1) |

kW |

21,7 |

34,0 |

45,7 |

63,7 |

87,2 |

106,1 |

133,1 |

164,6 |

|

(1) Cooling: external T 35 °C / R.H. 50% - internal T 27 °C / R.H. 47%

(2) Heating: external T 7 °C / R.H. 87% - internal T 20 °C / R.H. 60%

(3) Condensing

(*) On request reducible to 116 kW

NOTE: On request CF-XTRIM units are available with supplementary mixing box, air renewal and free-cooling (M-CFX) or with module for air recovery, renewal and free-cooling (M-RCFX).

HEAT EXCHANGER

Condensing gas heating with high thermal efficiency (up to 106%), with modulation from 100 to 30% of nominal heating capacity, offering hygienic combustion with low environmental impact (NOx in class 5) and good operational reliability. This technology has been specifically designed and developed to deliver the best solution for time variations in the thermal load, with important advantages in terms of energy savings and a subsequent reduction in operating costs.

SCROLL MULTI-COMPRESSORS

The use of tandem compressors operating in a single cooling circuit, with R410A, combined with the use of properly calibrated thermostatic expansion valves, allows the implementation of a high energy efficient solution, mainly at partial loads with maximum seasonal efficiency and a reduction in energy consumption.

EXTERNAL FANS

These are axial fans with a directly coupled motor, protected by safety grilles and characterized by high efficiency and low noise levels.

Optional EC version with electronic speed control that allows to:

- increase the operating range of the unit in cooling mode at low outdoor temperature

- further reduce the noise level

- reduce power consumption.

SUPPLY AND RETURN AIR VENTILATION

Made with highly energy-efficient centrifugal fans arranged for on-site airflow calibration.

FUNCTIONAL VERSIONS

- CF-Xtrim gas heating and thermodynamic cooling

- CF-Xtrim/P gas heating and reversible heat pump

- CF-Xtrim/F only thermodynamic cooling

- CF-Xtrim/HP reversible heat pump

CONFIGURATION WITH ACCESSORY MODULES

- M-CFX supplementary mixing box module with exhaust air extraction/expulsion fan, mixing section between recirculation and fresh air with 3 motorized dampers for free-cooling management.

- M-RCFX supplementary recovery module allowing energy to be recovered even from exhaust air through a direct thermal exchange with fresh air and to perform free-cooling when outdoor temperature conditions allow.

AIR QUALITY, THERMAL RECOVERY AND FREE-COOLING

- Standard filtration in class COARSE 60% (ex G4) with possible integration of accessory filters with efficiency up to ePM1 50% (ex F7).

- Air renewal with CO2 or VOC control for M-CFX integrative module.

- Free-cooling for M-CFX and M- RCFX integrative modules.

- Heat recovery between exhaust and fresh air achievable with the M-RCFX integrative module.

All configurations can be customized with the wide range of accessories provided for different installation needs.

The new generation of control electronics is designed to process the unit’s maximum energy efficiency, in combination with the supplementary modules, in the various operating conditions while ensuring maximum system reliability. With X-CONTROL it is possible to manage all the functions of the unit, control and adjust the operating parameters of both the air handling section and the thermodynamic section (cooling circuit).

X-CONTROL includes:

- PID control for the different functions and operating parameters, guaranteeing an energy optimisation logic when managing the various components comprising the unit, and allowing a reduction in operating costs;

- safety algorithms and alarms display;

- scheduling of operation over different time slots and daily profiles;

- RS485 serial interface – MODBUS communication protocol;

- PR-BASIC remote panel with keypad and display to remotely manage the single unit, or alternatively the PR-TOUCH, advanced touch-screen accessory version, to simultaneously manage up to 12 units.

PR-BASIC

PR-TOUCH

Main functions of X-CONTROL:

- automatic summer-winter switching;

- control and regulation of thermo-hygrometric parameters and air quality of the treated environment (with air quality probe accessory);

- dynamic set-point of treated room temperature, based on the external air temperature;

- operation at reduced capacity, for all needs of low thermal load in the building i.e. in the night hours when the required power is lower;

- intelligent defrosting based on effective thermodynamic needs that arise during heating operation;

- differentiated sequential start-up of multiple units serving the same system in case of start-up after power failure;

- automatic or manual free-cooling management.